press with moving column at constant speed.

Vertical thrust force during translation 150 Tons divided into 2 cylinders of 75 tons / each

Rapid descent speed 20 mm / sec

Working speed 5 mm / sec

Rapid rise speed 20 mm / sec

Translation speed in work 28mm / sec adjustable

Stroke of the cylinder 300mm

Span between open planes (without mounted supports and roller) about 800mm

Worktop height from the ground about 1.000mm

Longitudinal travel of the portal about 3.000mm electronically adjustable by means of a rotary transducer placed on the translation gearmotors

Width of the work surface about 1.300mm

Length of the worktop about 5,000 mm

"The descent speed of the press automatically changes to the working speed after reaching a certain pressure

The drive of the machine is of the electromechanical type for the translation of the upright, while the movement of the press cylinders is of the hydraulic type

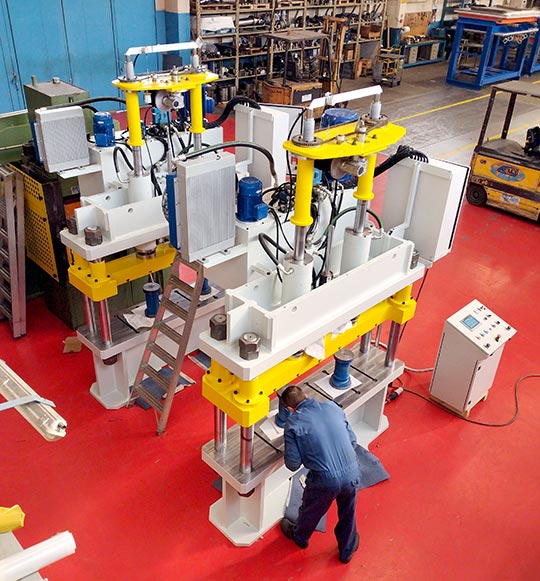

N°6 presses for high production.

Front light barrier protection

Screwed fixed net back protection

Right lateral protection structurally closed

Structurally closed left side protection

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 22 KW

Thrust force of main cylinder 10-60 Tons

Operator side horizontal light 700 mm

Vertical light 700 mm

Main cylinder stroke 500 mm

Height of the worktop from the ground 1000 mm

Lower worktop size 600x500 mm

Dimension of the mobile worktop 600x500 mm

Rapid descent speed 300 mm / sec

Working speed 20 mm / sec

Rapid ascent speed 300 mm / sec

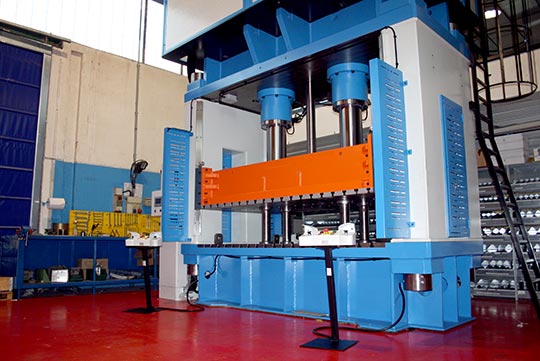

Press for molding fittings.

Front protection of optical barriers

Screwed rear guard protection

Right side protection screwed carter

Left side protection screwed carter

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 80 KW

Thrust force of the main cylinder 350 Tons

Operator side horizontal light 1000 mm

Side horizontal light 1000 mm

Vertical light 1,400 mm

Stroke of the main cylinder 1,000 mm

Height of the worktop from the ground 850 mm

Lower worktop size 1000x1000 mm

Mobile worktop size 1000x1000 mm

Fast descent speed 200 mm / sec

Working speed 20 mm / sec

Fast ascent speed 200 mm / sec

press for heat sinks.

60 ton power press equipped with dissipator handling system during pressing operations.

600tonn horizontal press for heat sinks.

Piece loading and unloading plane perpendicular to the horizontal pressing plane

Installed power 52 KW

Thrust force of the main cylinder 600 Tons

Main cylinder stroke 600 mm

Height of the worktop from the ground 900 mm

Useful worktop size 1600x1000 mm

Fast output speed 50 mm / sec

Working speed 5 mm / sec

Quick return speed 50 mm / sec

Press with heating plates for molding car pavilions.

Press complete with heating plates

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 55 KW

Thrust force of main cylinder 100 Tons

Operator side horizontal light 2700 mm

Lateral horizontal light 2000 mm

Vertical light 1400 mm

Main cylinder stroke 1200 mm

Height of the worktop from the ground 1100 mm

Lower worktop size 3200x1600 mm

Mobile worktop size 3200x1600 mm

Fast descent speed 350 mm / sec

Working speed 3.5 mm / sec

Fast ascent speed 350 mm / sec

1000 tonn press for mold testing and mini-series.

Front protection photoelectric barriers

Rear photoelectric barriers protection

Left side protection screwed carter

Right side protection screwed casing

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 68 KW

Thrust force of main cylinder 1000 Tons

Thrust force of compensating cylinders 200 Tons

Operator side horizontal light 5600 mm

Side horizontal light 1490 mm

Vertical light 1500 mm

Main cylinder stroke 1000 mm

Stroke of compensating cylinders 250 mm

Height of the worktop from the ground 1420 mm

Dimension of the lower worktop 4750x2320 mm

Dimension of the mobile worktop 4750x2320 mm

Fast descent speed 150 mm / sec

Working speed 4-12 mm / sec

Fast ascent speed 60 mm / sec

Stainless steel and super-wood deep drawing press.

Front protection - PHOTOELECTRIC BARRIER

Rear protection - FIXED SCREWED HOUSINGS

Right side protection - CLOSED SIDE

Left side protection - CLOSED SIDE

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 30 KW

Thrust force of main cylinder 300 Tons

Pushing force for sheet metal pressing cylinder 30 Tons

Operator side horizontal light 1340 mm

Vertical light 800 mm

Main cylinder stroke 700 mm

Stroke cylinder press sheet 300 mm

Height of the worktop from the ground 1200 mm

Lower worktop size 1200x800 mm

Mobile worktop size 1200x800 mm

Dimension of the worktop press plate 860x500 mm

Fast descent speed 100 mm / sec

Working speed 3 mm / sec

Fast ascent speed 100 mm / sec.

PRESS ADAPTED TO RECTANGING WORKS OF BIG CARPENTERIES .

- - WITH THIS TYPE OF PRESS IT IS POSSIBLE TO WORK THE PART TO BE STRAIGHTENED ANYWHERE WITHOUT MOVING IT FROM THE INITIAL POSITION.

- MOVING HEAD PRESS WITH MOTORIZED MOVEMENTS

- POWER 400TON

- USEFUL WORKTOP 4000x2000MM

- LIGHT BETWEEN PISTON AND WORKING TOP 800MM

- 500MM STROKE

- DESCENT / ASCENT SPEED 28MM / SEC

- WORKING SPEED 3MM / SEC

- ENGINE INSTALLED 15kW

- COMPLETE WITH N ° 04 COUPLE OF CYLINDERS FOR LIFTING MATERIAL WITH 50MM STROKE

- COMMAND OF REAR DISTRIBUTOR PRESS WITH SELF-LEARNING SYSTEM

- CONTROL OF THE "CRANE" TYPE PUSH BUTTON PRESS

- PRESS EQUIPPED WITH SYSTEM FOR “INDUSTRY 4.0” WITH INDUSTRIAL PLC CONNECTED TO THE COMPANY PLC SYSTEM

- COMPLETE WITH LIMIT SWITCH FOR ADJUSTING THE TRAVEL UP / DOWN, RIGHT / LEFT AND FORWARD / BACK

- PRESS DIMENSIONS 6000x4500x3700MM

- WEIGHT 42.000 KG

DEEP DRAWING PRESSES.

PRESS "A"

- THRUST FORCE MAIN CYLINDER 120 Tonn.

- STRENGTH OF MAIN CYLINDER TRACTION 20 Tonn.

- THRUST FORCE OF THE BLANK HOLDER CYLINDER 60 Tonn.

- HORIZONTAL LIGHT ON THE OPERATOR SIDE 845/1020 mm. mm.

- VERTICAL LIGHT 1200 mm.

- MAIN CYLINDER STROKE 950 mm.

- STROKE CYLINDER STROKE 400 mm.

- HEIGHT OF THE WORKTOP FROM THE GROUND 1510/1570 mm.

- DIMENSION OF THE LOWER WORK PLANE 800X800 mm. / 1000X1000 mm.

- SIZE OF THE MOBILE WORKTABLE 800X800 mm. / 1000X1000 mm.

- SIZE OF THE BLANK SHEET WORK PLAN 550X550 mm. / 600X600 mm.

- FAST DESCENT SPEED 500 mm./sec.

- WORKING SPEED 36/70 mm./sec.

- FAST ASCENT SPEED 500 mm./sec.

- CYLINDER EXTRACTOR IN THE MIDDLE OF THE MOBILE POWER PLANE 10 Tonn. STROKE 300 mm.

PRESS "B"

- THRUST FORCE MAIN CYLINDER 200 Tonn.

- STRENGTH OF MAIN CYLINDER TRACTION 25 Tonn.

- THRUST FORCE OF THE BLANK HOLDER CYLINDER 100 Tonn.

- HORIZONTAL LIGHT ON THE OPERATOR SIDE 920/1020 mm.

- VERTICAL LIGHT 1100 mm.

- MAIN CYLINDER STROKE 700 mm.

- STROKE CYLINDER STROKE 300 mm.

- HEIGHT OF THE WORKTOP FROM THE GROUND 1400 mm.

- DIMENSION OF THE LOWER WORK PLANE 900X900 mm. / 1000X1000 mm.

- SIZE OF THE MOBILE WORKTABLE 900X900 mm. / 1000X1000 mm.

- SIZE OF THE BLANK SHEET WORK PLAN 600X600 mm. / 600X600 mm.

- FAST DESCENT SPEED 500 mm./sec.

- WORKING SPEED 27/63 mm./sec.

- FAST ASCENT SPEED 500 mm./sec.

- CYLINDER EXTRACTOR IN THE MIDDLE OF THE MOBILE POWER PLANE 3 Tonn. STROKE 200 mm.

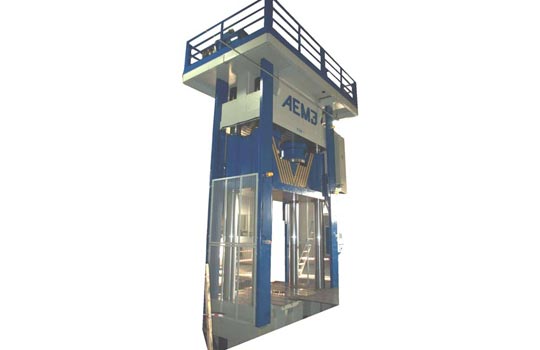

PRESSES SUITABLE FOR THE PRODUCTION OF STAINLESS STEEL DRUMS.

AEM3

PRESS

- THRUST POWER 300 Tonn

- TOTAL ELECTRIC POWER INSTALLED 30 + 30 Kw

- OPERATOR SIDE LIGHT 3000 mm.

- LATERAL LIGHT 1300 mm.

- VERTICAL LIGHT WITH FULLY OPEN PRESS 1300 mm.

- VERTICAL LIGHT WITH FULLY CLOSED PRESS 300 mm.

- WORKING AREA DIMENSIONS 3000X1700 mm.

- CYLINDER STROKE 1000 mm.

- WORKTOP HEIGHT 900 mm.

- PRESS OVERALL 4000X2300 mm. HEIGHT 5500 mm.

- FAST DESCENT SPEED 200 mm./sec.

- WORKING SPEED AT MAXIMUM POWER 5 mm./sec.

- FAST ASCENT SPEED 200 mm./sec.

PRESS DESIGNED WITH A HYDRAULIC AND ELECTRIC SYSTEMS WITH VECTOR-CONTROLLED INVERTER MOTORS AND POWER SUPPLIES FOR ENERGY CONTAINMENT

ENERGY SAVINGS UP TO 40%

PRESS IN THE COMPLETION PHASE

“TEST MOLDS” LARGE DIMENSIONS PRESS. CUSTOMER WORKING IN THE "AUTOMOTIVE / SHEET METAL" SECTOR FOR MOLDING.

- POWER 2000 TON

- LIGHT BETWEEN THE COLUMNS 1600X1000mm

- USEFUL WORKTOP OF 1600X1600mm

- LIGHT BETWEEN THE OPEN PLANS 1400mm

- STROKE OF THE PISTON 1000mm

- DESCENT / ASCENT SPEED 200mm / sec

- WORKING SPEED 25-8mm / sec

- HYDRAULIC SYSTEM BRAND "REXROTH"

- ELECTRICAL SYSTEM BRAND "SIEMENS" AND OPERATOR PANEL BRAND "PROFACE"

- COMPLETE WITH LADDER FOR ACCESS TO THE TOP OF THE CONTROL UNIT

- COMPLETE WITH 02 “SITEMA” FOR FALL ARREST CONTROL

CARBON FIBRE PRESS.

- ADJUSTABLE WORKING FORCE 50

- 1,000 tons

- USEFUL LIGHT AMONG THE OPERATOR SIDE COLUMNS 2100 mm.

- USEFUL LIGHT AMONG THE LATERAL COLUMNS 1100 mm.

- STROKE OF THE MOBILE FLOOR 1600 mm.

- LIGHT BETWEEN OPEN WORKTOPS 2500 mm.

- LIGHT BETWEEN WORKING PLANS CLOSED 900 mm.

- APPROXIMATION SPEED 300 mm / sec.

- DECELERATION SPEED 80 mm / sec.

- WORKING SPEED 0 - 10 mm / sec.

- RETURN SPEED 300 mm / sec.

- TANK WITH CAPACITY OF ABOUT 1600 lt.

- POWER OF MOTORS INSTALLED ABOUT 110 Kw.

- SIDES COMPLETELY CLOSED FOR SMOKE EXTRACTION.

PRESS SUITABLE FOR WORKING OF HOT FORGING IN BRASS PARTS AND COLD STAMPING OF METAL PARTS.

- "CLOSED SHOULDER" PRESS WITH PRISMATIC GUIDES

- 1000TON POWER

- USEFUL WORK TABLE 1500x1500MM

- LIGHT BETWEEN PISTON AND LOWER TOP 900MM

- PISTON STROKE 400MM

- APPROACH SPEED 200MM / SEC

- WORKING SPEED AUTOMATICALLY ADJUSTABLE ACCORDING TO THE EFFORT THAT IS 25-5MM / SEC

- RETURN SPEED 200MM / SEC

- PRESS EQUIPPED WITH 300TON STRIKER 200mm STROKE WITH 860x420MM WORKTOP

- IFERIORE FLOOR WITH 40 HOLES DIAM. 40MM FOR CANDLE PASSAGE

- PRESS EQUIPPED WITH SELF-LEARNING SYSTEM WITH PLC "SIEMENS" AND TOUCH SCREEN BRAND "PRO FACE"

- POSSIBILITY TO SAVE UP TO 200 DIFFERENT PROGRAMS

- HYDRAULIC SYSTEM BRAND DENISON / PARKER

- OPTICAL BARRIERS OF LEVEL IV BRAND "KEYENCE" MOUNTED ON THE OPERATOR SIDE AND FIXED PROTECTION ON THE NET ON THE OPPOSITE SIDE OF THE OPERATOR

- ENGINES INSTALLED WITH A TOTAL POWER OF ABOUT 95kW

- PRESS DIMENSIONS 3.300x2.500x5.500mm

- WEIGHT 40.000Kg

AUTOMATIC PIPE CALIBRATION MACHINE.

- PRESS CALIBRATING MACHINE 4000TON TO CALIBRATE WELDED TUBES (MADE FROM METAL) FROM DIA. A 168MM DIA. 1250MM THICKNESS FROM 10MM TO 70MM STAINLESS STEEL

– DUPLEX

- SUPERDUPLEX

- POWER EXTRACTION 250TON

- LOAD HANDLING ON A ROLLER TUBE ANTERIOR AND POSTERIOR

- TRANSLATION AND ROTATION PIPE FULLY AUTOMATED WITHOUT A CRANE

- WITH POWER PULLER 50TON POSITION ON THE PLAN MOBILE

- MOVING OUT OF AUTOMATED MOULD DIE LOCK HYDRAULIC OPERATION UNLOADING / LOAD PRACTICABLE DIES IN 5 MINUTES WITH MAXIMUM DIE ALREADY PLACED

- TOTAL POWER ENGINE INSTALLED ABOUT 300KW

- ALL INSTALLED ENGINES ARE EQUIPPED WITH INVERTER THAT ALLOW AN ENERGY SAVING UP TO 50%.

PRESS BRAKE - 4200 ton.

- PRESS WITH SPECIAL DRAWINGS 4200 ton.

- BENDING PRESS

- BENDING LENGTH 13000 mm

- MACHINE LENGTH 14000 mm.

- MACHINE HEIGHT 6000 mm.

- UNMATCHED BENDING PRECISION!

- HEMMING PRESS, LARGE SIZE BENDING PRESS, SYNCHRONIZED BENDING PRESS.

PRESS FOR SIMULTANEOUS 2 FOLDS.

- IDEAL FOR BENDING OF CALL ON TUBES WITH DIAMETER 10 "3/4 (858 mm. WIDTH PLATE) A D.48" (3830 mm. WIDTH PLATE) AND THICKNESS UP TO 60 mm. THIS ALLOWS YOU TO FOLD THE PRINCIPLE OF WORKING HALF THE TIME

- PRESS "COLUMNS 4"

- POWER 3000 ton. (N° 2 CYLINDERS 1500 ton. / CAD)

- LIGHT BETWEEN THE COLUMNS 4100X600 mm.

- LIGHT BETWEEN PLANS OPEN 1500 mm.

- STROKE OF HYDRAULIC CYLINDER 450 mm.

- SPEED 'DOWN / UP 200 mm/sec - SPEED 'MAX POWER AT WORK 10 mm/sec

- VALVES EQUIPPED WITH CONTROL OF THE PRESS TO LEARNING SYSTEM AND FULL OF SAVING RECIPES, CYCLES TOTAL, PARTIAL CYCLES.

PRESSE FOR FORGING

- Power 800 Ton

- Light between the shoulders facing press 1.300 mm.

- Side Light 900 mm.

- Vertical size between the open tops 800 mm.

- Cylinder stroke 600 mm.

SYSTEM CALIBRATION PIPES.

- PIPE-SIZING EQUIPMENT

- “PILLAR” PRESS WITH “LINEAR” BEARINGS

- TWO-SPEED POWER DRIVEN AUTOMATIC EXCHANGE OLEO-DYNAMIC PRESS

- POWER 2500 TONS SPAN 2000X2000 mm.

- SPAN BETWEEN OPEN SURFACES 2000 mm.

- CYLINDER STROKE 1100 mm.

- SPEED 200/50/10/5 mm/sec

- COMPLETE WITH 20 ton. OLEO-DYNAMIC EXTRACTING PISTONS, STROKE 650 mm. and 40 ton. EXTRACTOR WITH SADDLES ON THE BOTTOM PART, STROKE 550 mm.

SYSTEM FORMING PIPES HOT.

- POWER 1500 ton.

- SPAN 2500x600x2600 mm.

- COLUMN DIAM. 400 mm.

- STROKE 1800 mm.

- SPEED DOWN / UP 100 mm/sec

- SPEED WORK 15 mm/sec

- POWER INSTALLATION 200 kW

- COMPLETE WITH 250 ton. LOWER BLANK HOLDER STROKE 2300 mm.

- COMPLETE WITH EXTERNALLY SLIDING BOLSTER TO CHANGE MOULDS TO 830X1350X110 mm.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES LEVEL IVPROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL.

PIPE FORMING SYSTEMS.

- “PILLAR” PRESS WITH “LINEAR” BEARINGS

- USED FOR MANUFACTURING WELDED DUPLEX AND SUPER DUPLEX STAINLESS STEEL PIPES

- MAXIMUM 60 mm. THICK

- POWER 3500 ton.

- FRONT SPAN (OPERATOR’S SIDE) 2250 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- SPAN BETWEEN OPEN CYLINDER AND WORK TABLE 2000 mm.

- SPEED 200/10/200 mm/sec

- PRESS WITH SLIDING GUIDES

- COMPLETE WITH TWO 200 ton CYLINDERS STROKE 600 mm. FOR STRAIGHTENING THE PIPE-IN-PROCESS

- COMPLETE WITH FOUR 20 ton. CYLINDERS STROKE 650 mm. FOR ROTATION AND SLIDING OF THE PIPE-IN-PROCESS

- COMPLETE WITH TWO 20 ton. CYLINDERS STROKE 650 mm. FOR EXTRACTION OF THE PIPE-IN-PROCESS PLACED ON THE MOBILE PLANE

- COMPLETE ALSO WITH MOULD LOADING /UNLOADING

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

FORMING PRESS.

- “4 COLUMN” PRESS

- POWER 2000 ton. SPAN 2000x2000x1800 mm. CYLINDER STROKE 1100 mm.

- SPEED 200/50/10-5/200 mm/sec

- ELECTRONIC WORKING SPEED REGULATION COMPLETE WITH EIGHT 20 ton. UPPER AND LOWER EXTRACTORS

- STROKE 100 mm.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES, WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE OPERATOR’S BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES

- PRESS WITH UPPER BLANK HOLDER CUSHION.